The Patented Linear Cleaning method is the only solution to provide a full cleaning service guaranteed without shutdown or stop.

The installation can be cleaned completely while it remains in full production at extreme temperatures. Cleaning is done within the gas lanes of tube bundles, making for a more targeted and effective solution.

Using this method, not only are the blockages in the gas tubes cleared, the thermal efficiency is improved significantly also.

How it works

- Using infrared camera, the experts first determine the fouling area and decide cleaning methods

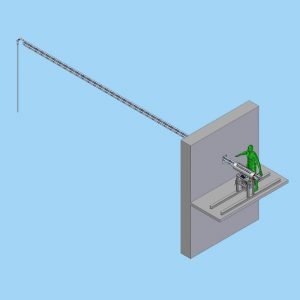

- From the access doors, small charges are directed via cooled lances to the fouled area of the installation

- The detonative cleaning charge is positioned at the determined location (i.e. super-heater or economizer)

- By creating small controlled precision shockwaves, the deposits are fractured from fouled surfaces without disturbing the unit’s integrity

- The whole system is controlled remotely to ensure safety throughout

- This process is repeated in grid patterns and at different elevations until the cleaning objective is met

Why this method?

- Patented Linear Cleaning is the proven solution for up to 200 installations worldwide

- Clean bundles up to six metres deep, even in the flue gas lines

- Longer bundles of up to 12 meters can be cleared, with lances custom-made for specific jobs

- Efficiency can be increased by up to 110%, meaning increased revenue

- Safer and more sustainable than traditional methods